EMC starts with a good design

A good design takes electromagnetic radiation into account, but sometimes additional measures are unavoidable. Specifically for all cases where an application, device, or machine needs to be provided with additional EMI shielding, Telerex offers a wide range of shielding tools such as gaskets, finger strips & contacts, integrated EMI sealings, wire mesh solutions, fabrics, and tapes.

Questions about finding the right EMC solution?

Do not hesitate to contact us!

Contact our EMC experts

EMC/EMI shielding

Shielding

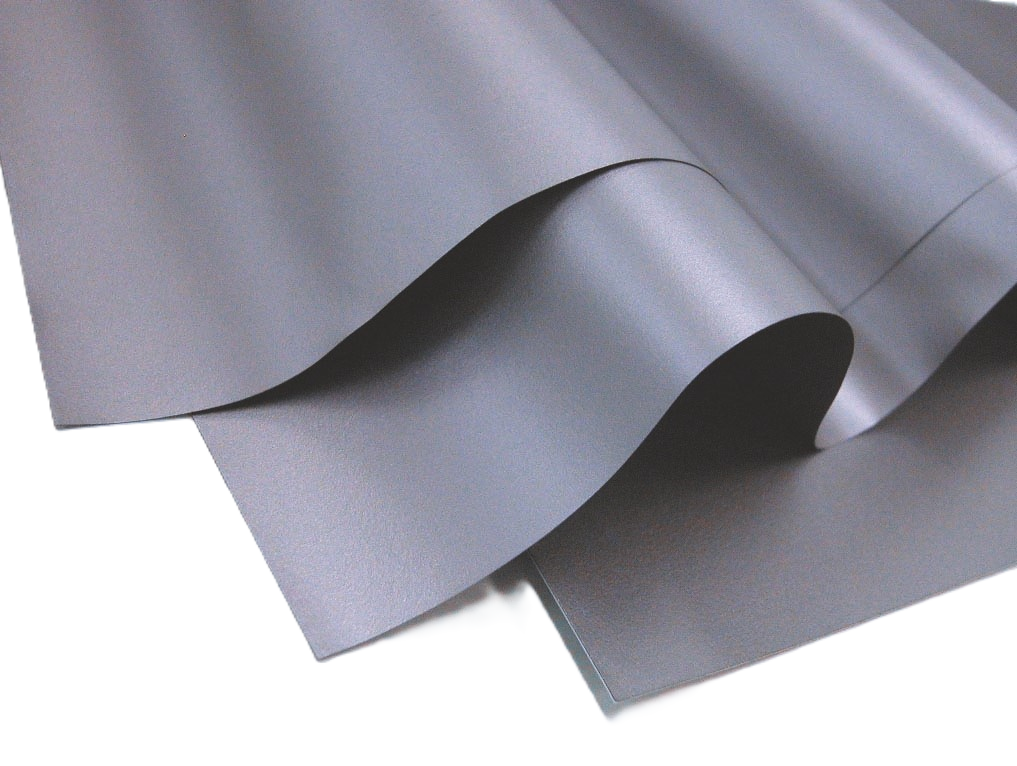

Shielding reduces electromagnetic interference (EMI) by blocking unwanted electromagnetic fields. This improves the electromagnetic compatibility (EMC) of electronic devices. We help you find the best type of shielding and product, and provide board level shielding, gaskets, finger strips and contacts, integrated EMI sealings, wire mesh solutions, fabrics, and tapes.

Filters

Filters in EMI/EMC design are crucial for reducing electromagnetic interference and ensuring device compatibility. They block unwanted noise and allow desired signals to pass through. Important features include attenuation, insertion loss, and the ability to handle specific frequencies and currents. We supply filters from Schaffner, among others.

Absorbers

Absorbers reduce unwanted electromagnetic radiation and prevent reflections. When choosing the right absorber, the frequency range is important as it can determine the type of absorber. Additionally, absorption efficiency and material properties such as type, thickness, and flexibility are important.

Enclosures

Metal enclosures play a crucial role in reducing and preventing EMC and EMI problems by blocking unwanted electromagnetic radiation and preventing internal components from causing interference. This ensures stable operation of electronic devices and helps meet EMC standards. We offer standard and custom enclosures from METcase, among others.

Discuss your application with our EMC experts to find the right sample

Request a sampleProjects and services we are proud of

Our EMC and thermal experts assisted in solving EMC and thermal issues in a kiosk application.

Read more

By providing custom EMC products, Telerex helps simplify the production process of a climate control solution.

Read more

Telerex supports many knowledge events. In 2024, we were the Platinum sponsor of the EMC Symposium 2024. Check out the events we are supporting this year.

All Telerex events

Product news for EMC product

Laird CoolZorb-MaxZorb

Laird introduceert hybride thermische/EMI absorber met thermische geleidbaarheid van 8,5W/m.K en verbeterde EMI-demping van 3GHz tot 90GHz

Read more

Schaffner introduces RT Series N

The RT-Series N delivers up to 15 dB higher attenuation performance than its ferrite-based predecessor

Read more

Laird introduces BMI-S-608

Expansion of shielding functionality and cost savings

Read more

Brands we work with