Welcome to Telerex

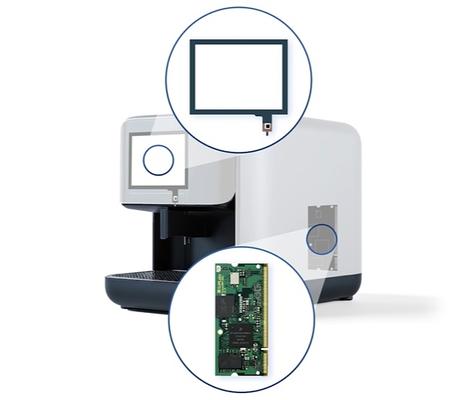

We have been specialists in electronic and electromechanical products since 1970. We support OEMs with technical advice, global sourcing, and an optimized supply chain.

Discover our webshop!We help you create the optimal product

The best products

We ensure that your final product performs optimally by advising you on the best products and modules

A simplified supply chain

We simplify your supply chain through global procurement, precise planning, and timely delivery as agreed.

Supporting services

for faster time-to-market

We support your success with in-house assembly of prototype series, built-to-order solutions, product compliance documentation, and thermal and EMC services.

The areas of expertise of Telerex

Personal touch

We believe in a personal touch! You have direct access to our customer service, account management, engineering, and finance staff – just give us a call or send an email.

Stay up to date with Telerex Tech Talks

Projects we are proud of

Need a power supply immediately?

Find the right power supply in our webshop

Do you need a specific power supply or want to know which power supplies meet your specifications? We can supply hundreds of power supplies. Check our webshop.