Welkom bij Telerex

Wij zijn sinds 1970 specialist in elektronische en elektromechanische producten. We ondersteunen OEM’s met technisch advies, wereldwijde sourcing en een geoptimaliseerde supply chain.

Ontdek onze webshop!Wij helpen u met het maken van het optimale product

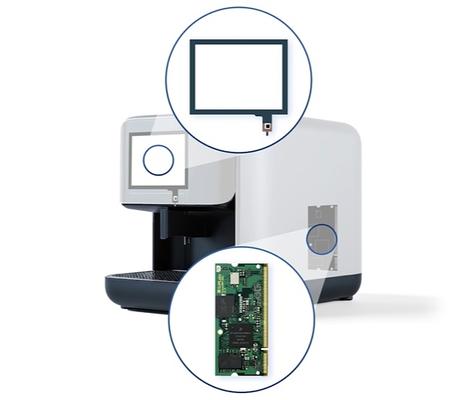

De beste producten

We zorgen ervoor dat uw eindproduct optimaal presteert door u te adviseren over de beste producten en modules.

Eenvoudige supply chain

Wij vereenvoudigen uw supply chain door wereldwijde inkoop, nauwkeurige planning en tijdige levering volgens afspraak.

Ondersteunende diensten voor een

snellere time-to-market

Wij ondersteunen uw succes met in-house assemblage van proefseries, built-to-order oplossingen, product compliance documentatie en thermische en EMC diensten.

De expertise gebieden van Telerex

Thermische en EMC/EMI diensten

Persoonlijk contact

Wij geloven in persoonlijk contact! U heeft direct contact met onze medewerkers van customer service, account management, engineering en finance – gewoon even bellen of mailen.

Blijf op de hoogte met Telerex Tech Talks

Projecten waar we trots op zijn

Direct een power supply nodig?

Vind de juiste voeding in onze webshop

Heeft u een specifieke voeding nodig of wilt u weten welke voedingen aan uw specificaties voldoen? Wij kunnen honderden voedingen leveren. Kijk in onze webshop.